Frictional instabilities as an alternative to friction coefficient in fine touch perception

Figures

Mechanical testing and determination of frictional instability landscape in samples.

(A) Schematic of friction testing apparatus. An elastomeric mock finger is connected to a force sensor and motorized stage. The mock finger was driven at four different driving velocities (v=5–45 mm/s) at four different applied masses (M=0–100 g, in addition to the deadweight of the mock finger), mimicking human exploration. (B) Representative force curves of three types of frictional instabilities. Steady sliding (SS, orange) shows no distinctive feature besides high frequency force oscillations due to stick-slip, which is above the electronic sensor noise. Slow frictional waves (SFW, blue) are slower, large amplitude oscillations corresponding to global or coherent stick-slip of the entire mock finger. Stiction spike (Sp, green) is where a single, large-magnitude stick-slip event is observed at the onset of steady sliding. (C) Phase maps of frictional instabilities across all surfaces. Colors and intensities correspond to the type and frequency of each instability, respectively, at a given condition. Color map created by linear interpolation between experimental conditions, with location of conditions tested indicated by gray (×) marks.

Human subjects testing for discriminability between surfaces.

(A) Average accuracies of all pairs in a 3-AFC task. All pairs were statistically significantly distinguishable above chance (red line, 33%). Error bars are represented as 95% confidence intervals around the means. Ends of brackets with (*) above denote statistically significantly different accuracy rates. (B) Generalized linear mixed model (GLMM) of human discrimination accuracy during fine touch vs. the differences in steady sliding events determined by the mock finger. Accuracies of each trial across all subjects represented by gray ○ marks, and global averages represented by blue × marks. (C) GLMM of response times vs. the differences in stiction spike events. P2 and P3 have the same x-axis value and are shifted for clarity. Mean times are represented by blue (×) marks, while medians are represented by red lines at notches of box plots. (D) GLMM of accuracy vs. difference in average friction coefficient (), showing a negative correlation. (E) GLMMs of accuracy vs. other commonly used material properties or parameters: ΔAverage roughness Ra, ΔHurst exponent H, and ΔWater contact angle hysteresis (°) (N=10 participants, n=600 total trials).

Recording friction of a human finger exploring a surface.

(A) Setup to measure tangential and normal forces during fine touch. A coated sample is securely double-sided taped to a stage, connected to two red sensors to record tangential and normal forces. A motion tracker is also placed on the moving finger to record displacement while sliding. Two setups are used simultaneously, one for each hand. (B) Formation of all instability phases during human exploration. (C) Tangential forces experienced by two hands on the same surface chemistry.

Surface characterization via atomic force microscopy.

(A) Height profiles of surfaces obtained via AFM in tapping mode. All scale bars are 2 µm. (B) Respective 2D fast Fourier transforms of surface topographies. All scale bars are 10 µm–1. (C) 2D power spectral densities of all surface profiles, plotted as log(PSD) vs. log(spatial frequency) to calculate Hurst exponents.

XPS survey scans of surfaces.

C, N, and O peaks indicate evidence of binding onto Si wafers after deposition. Plotted as intensities normalized by the O peaks vs. binding energy.

DI water droplets on surfaces, representative images used to measure advancing angles.

All scale bars are 1 mm.

Force traces with less distinct categorization.

Left: stiction spike with small height, right: stiction spike followed by small oscillations.

GLMM fits of participant accuracy vs. the differences in instability incidence for individual instability types.

Left: accuracy vs. differences in formation of slow frictional waves (SFW) between pairs. P1 and P5 have the same x-axis value and are shifted for clarity. Right: accuracy vs. differences in formation of stiction spikes (Sp).

GLMMs of accuracy vs. more material parameters or properties across N=10 participants.

(A) Left: root-mean-square roughness Rrms, right: velocity-dependent Bowden-Tabor friction coefficient across all conditions (µ). (B) GLMM fit of response times vs. differences in Hurst exponent H. Mean times are represented by blue × marks, while medians are represented by red lines at notches of box plots.

Tables

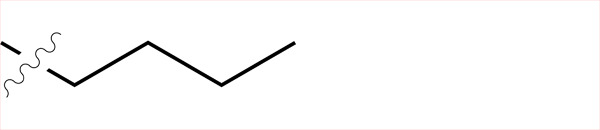

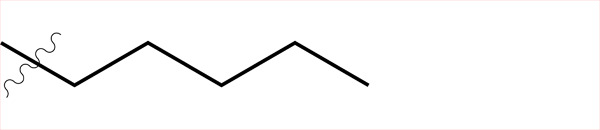

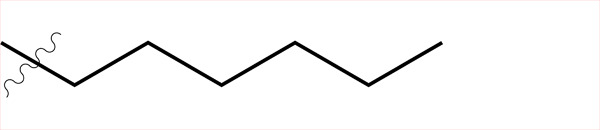

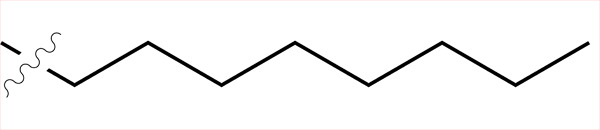

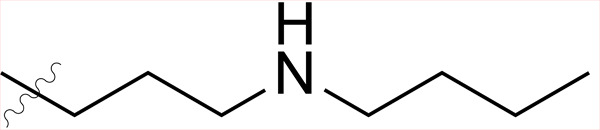

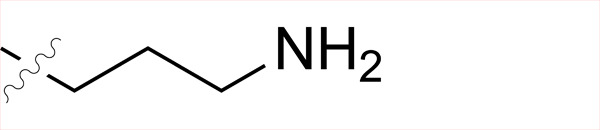

Surface characterization of silanized silicon wafers.

| Sample | Surface structure | Average roughness(Ra, pm) | Contact angle(advancing - receding ± σHysteresis, °) | Average friction coefficient () | Friction coefficient interquartilerange(μQ3 - μQ1) | Hurst exponent(H) |

|---|---|---|---|---|---|---|

| C4 |  | 861 | (99.06–103.74)±2.5 | 2.21 | 1.24 | 0.56 |

| C5 |  | 443 | (100.18–109.68)±2.6 | 2.45 | 2.09 | 0.22 |

| C6 |  | 858 | (102.42–109.10)±5.1 | 2.49 | 1.74 | 0.29 |

| C8 |  | 431 | (108.38–114.32)±4.0 | 3.04 | 2.08 | 0.06 |

| C4-APTMS |  | 358 | (54.74–59.44)±3.9 | 2.06 | 1.20 | 0.04 |

| APTMS |  | 280 | (49.80–58.28)±5.7 | 2.03 | 1.54 | 0.15 |

Pairs of samples for human testing by their frequency of instability formation.

| Label | Samplecomparison | |ΔSS| | |ΔSFW| | |ΔSp| | |||

|---|---|---|---|---|---|---|---|

| Count | % | Count | % | Count | % | ||

| P1 | C4 vs C4-APTMS | 20 | 13.9% | 16 | 11.1% | 4 | 2.78% |

| P2 | C6 vs C4-APTMS | 9 | 6.25% | 27 | 18.8% | 14 | 9.72% |

| P3 | C4 vs C5 | 11 | 7.64% | 21 | 14.6% | 14 | 9.72% |

| P4 | C8 vs C4-APTMS | 14 | 9.72% | 34 | 23.6% | 2 | 1.39% |

| P5 | C4 vs APTMS | 24 | 16.7% | 16 | 11.1% | 8 | 5.56% |

| P6 | C5 vs C4-APTMS | 31 | 21.5% | 23 | 16.0% | 18 | 12.5% |

Additional files

-

MDAR checklist

- https://cdn.elifesciences.org/articles/104543/elife-104543-mdarchecklist1-v1.docx

-

Source data 1

Mechanical friction data.

- https://cdn.elifesciences.org/articles/104543/elife-104543-data1-v1.xlsx